For the management and control of industrial production processes is necessary to keep quality control over the entire production, trough a systems that allows immediate response and quick corrections.

The integration of the specific technology supports customers to improve the effectiveness, precision and speed of production processes, making AT Automation a key supplier for different sectors such as environment, food industry, manifactury, siderurgic, with a focus on the industry of aluminum.

The available technology consists in

- advanced tools for the integration in the process and its supervision;

- programmable logics for the treatment of analog and digital signals;

- integration with field networks and of remote control systems.

The comapany manages also analysis for Transition 4.0, CE certifications for plants and machines in use, instrumental calibration for certification ISO 9000.

PROCESS AUTOMATION AND MACHINE EQUIPMENT

AT realizes innovative applications for the optimization of production, through the use of advanced instrumentation for the integration in the process and its supervision, of programmable logics for the treatment of analog and digital signals and integration with field networks and of remote control systems.

SWITCHBOARDS

AT Automation designs and manufactures electrical and electromechanical panels in compliance with IEC, CEI, VDE, NEMA, CSA or UL standards, taking care of all phases from the project to the assembly, installation and start up online always performed with the utmost care and reliability.

The company is certified DM 37 08 for new construction and maintenance of industrial electrical systems and guarantee precision and reliability.

PROGRAMMABLE LOGICS AND FIELDBUS

Automation stands for Programmable Logic Controller (PLC). The processing of digital or analog signals, coming from sensors, actuators or other devices installed in any automatic system, requires the use of these intelligent and programmable units.

AT Automazione is qualified by Siemens as a “Simatic Solution Provider”, thanks to the skills gained in the development of applications for the control of machines and plants with Simatic PLC (S5 and S7, Profibus networks, and operator panels).

The skills accumulated over the years, however, allow us to work easily also with PLC Allen Bradley, Omron, etc.”

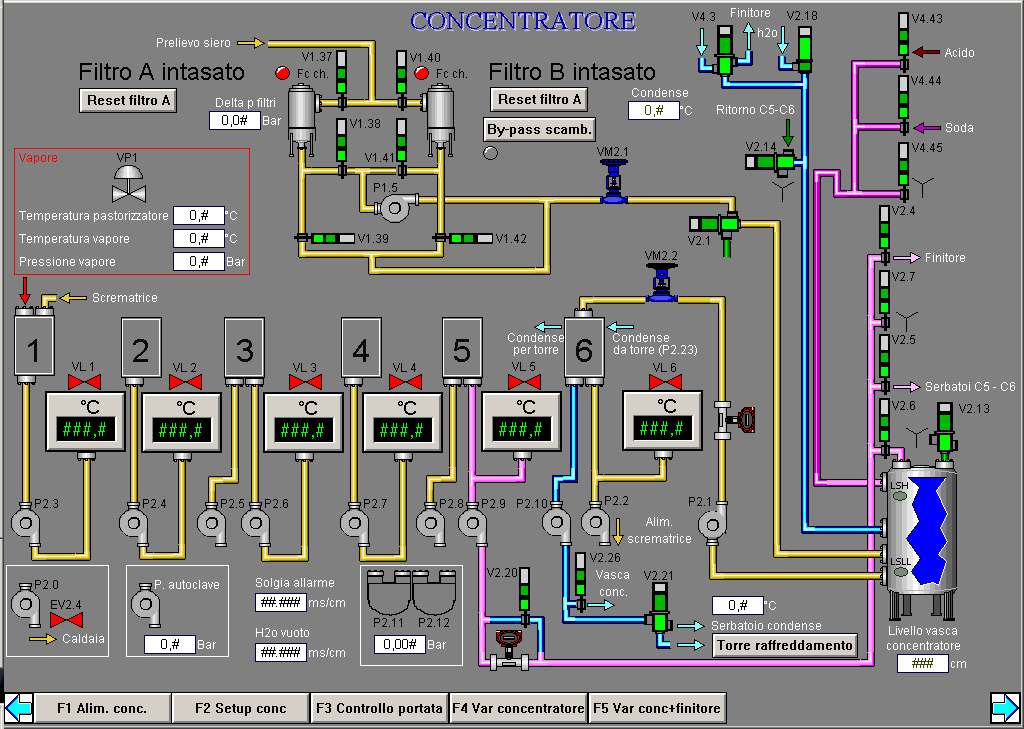

PROCESS SUPERVISION SYSTEMS

The high speed of modern production needs constant fast feedbacks from the production lines, allowing an immediate understanding to make necessary corrections and maintenance.

AT Automation supervision systems process data from programmable logics or directly from field sensors.

The solution provided is Wonderware’s Intouch software, successfully used in multiple fields such as casting machines, test benches, food and wine sectors, management of road tunnels.

Intouch Wonderware system guarantees a stable platform with which to manage and monitor processes, providing real-time messages, graphic summaries, managing alarms intended for operators or service centers 365 days a year, 24 hours a day.

AT Automation has experience in the development of customized applications with on-board control panels, SCADA-HMI systems, using reliable products, such as WinccFlexible from SIEMENS or SuperFlash from AUTOMA.